Binary Star DS-1700T double-sided Inkjet Inkjet Printer adopts the mechanical structure of synchronous vertical parallel movement of two carriages, we have the patent of feeding and take up structure, which can realize the materials’ both sides printing at the same time, the pattern alignment is very accurate so the production of high-quality orders is easily completed.

The biggest advantage of this double-sided Inkjet Printer is the customization of differentiated programs, which can perfectly realize the application of different programs such as “ Same image same color; Same image different color; Different image different color ”. To achieve the best color saturation and finished product effect of the materials through the control of ink volume on both sides. Our double-sided Inkjet Printer can get good printing results and the operation is simple and convenient as well.

Product Advantages

Use constant tension feeding and takeup system of textile equipment, magnetic powder controls feeding and takeup,110mm double rubber covered rollers feeding cloth, can be adjusted freely according to the thickness and tension of the material.

To collect the micro-particle ink in the air generated during printing, each carriages has two collection devices, total four devices.

Automatic nozzle ink press and cleaning device, save time. When the device is out of use, the nozzle moisturizes reliably.

Features

High-speed dual-carriage CMYK system delivering flexible, automated, clean printing with advanced Epson i3200 control.

- CMYK four-color staggered Epson i3200-A1 printhead configuration

- Dual-row printheads enable high-speed, stable output

- Flexible image size and color permutation settings

- Automatic ink purge and cleaning system

- Dual carriages with synchronized roll-to-roll adjustment

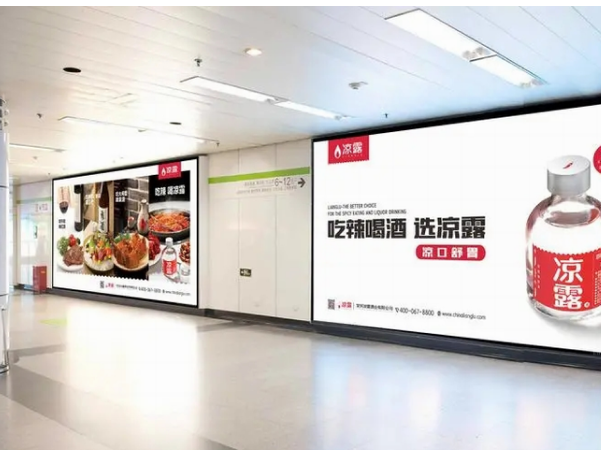

Production Example of Binary Star DS-1700T